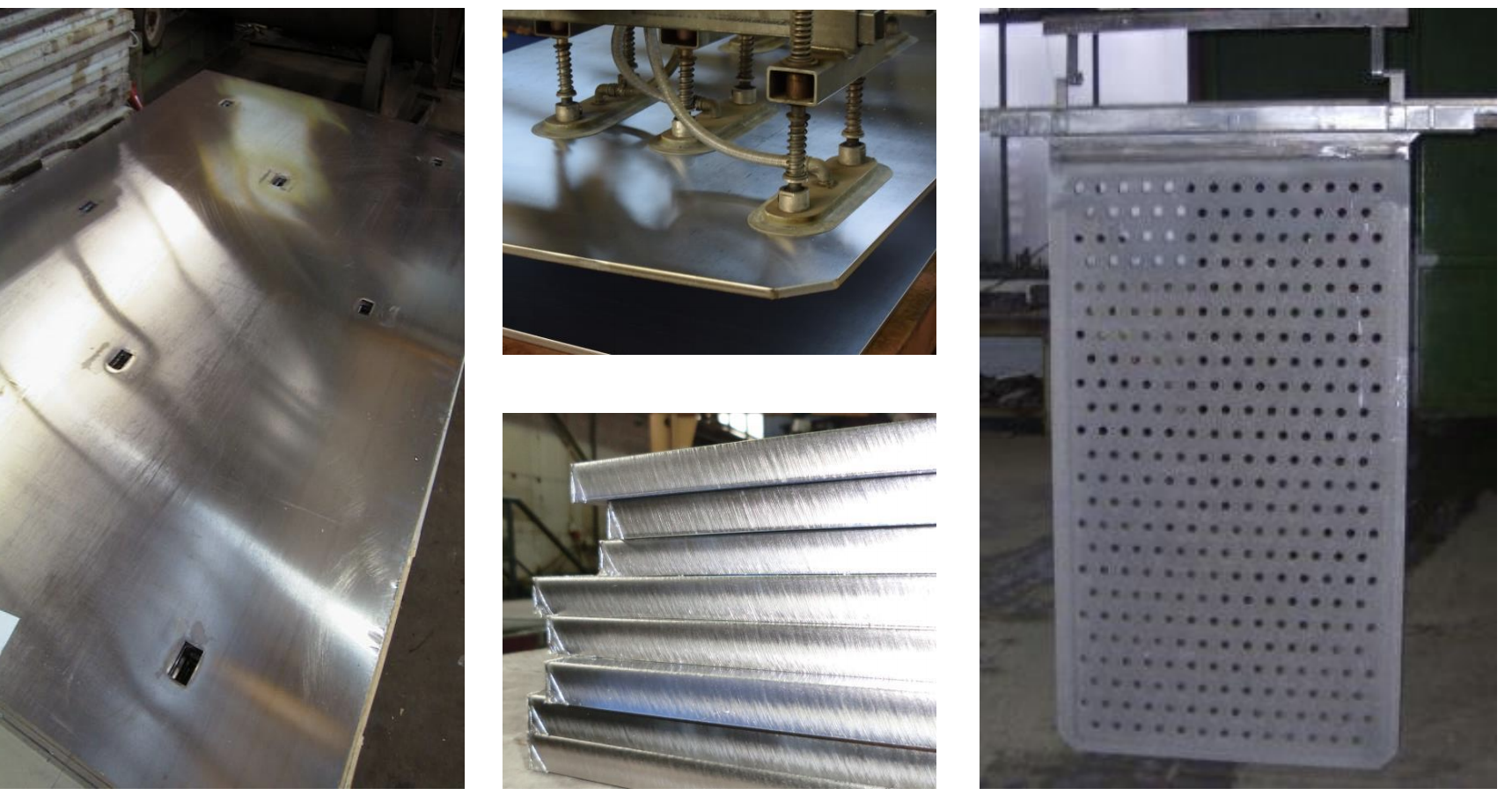

Our High Performance Rolled Pb-alloy Anodes for metal extraction provides for significantly higher current efficiency, lower power consumption, and longer service life compared to Cast Anodes due to higher resistance to deformation & corrosion resistance.

Our patented Zn-Stripping machine, with integrated pre-stripping for Cathodes, with or without discs, offers faster Stripping, simultaneously taking outstanding care of the Cathodes, with improved reliability and less frequent maintenance giving more time for Cell Hall management.

Tank House Crane is double-pantograph synchronization, ensuring stable handling & fast speeds. It is equipped with valveless Drip Pan & powered via multipole Busbar, suitable for powering multiple Cranes, and a 500m range high-precision dual laser positioning, compensating for civil work imperfections.

METTOP-BRX Technology is an economical way to increase production and productivity in new and existing electro-refining tank houses. It allows up to a 50 % increase in current density, even at high current efficiency, while still maintaining good cathode quality or even improving it. This new, patented technology, presently available for Copper, helps reduce both opex and capex.

Servo-driven CSM, APS & ASWS machines with Robotic material handling for Cu, Ni, Co Electro Refining or SX/EW, with Split or V-sheets; manual or automatic; providing strapping, labelling, weighing, corrugating, clinching, etc. CSM's are equipped with smart stripping algorithms optimising stripping process, minimising reject Cathodes increasing productivity, and reducing refurbishment and replacement costs.

CAID ITACC-XL Cathodes with Solid Copper Bar design maintains low resistance over a wide range of temperatures, therefore handling higher current densities without overheating. CAID Cathodes are No.1 in electrical efficiency and repairability, with over a million Cathodes in service providing highest current efficiencies to Tank Houses around the world.

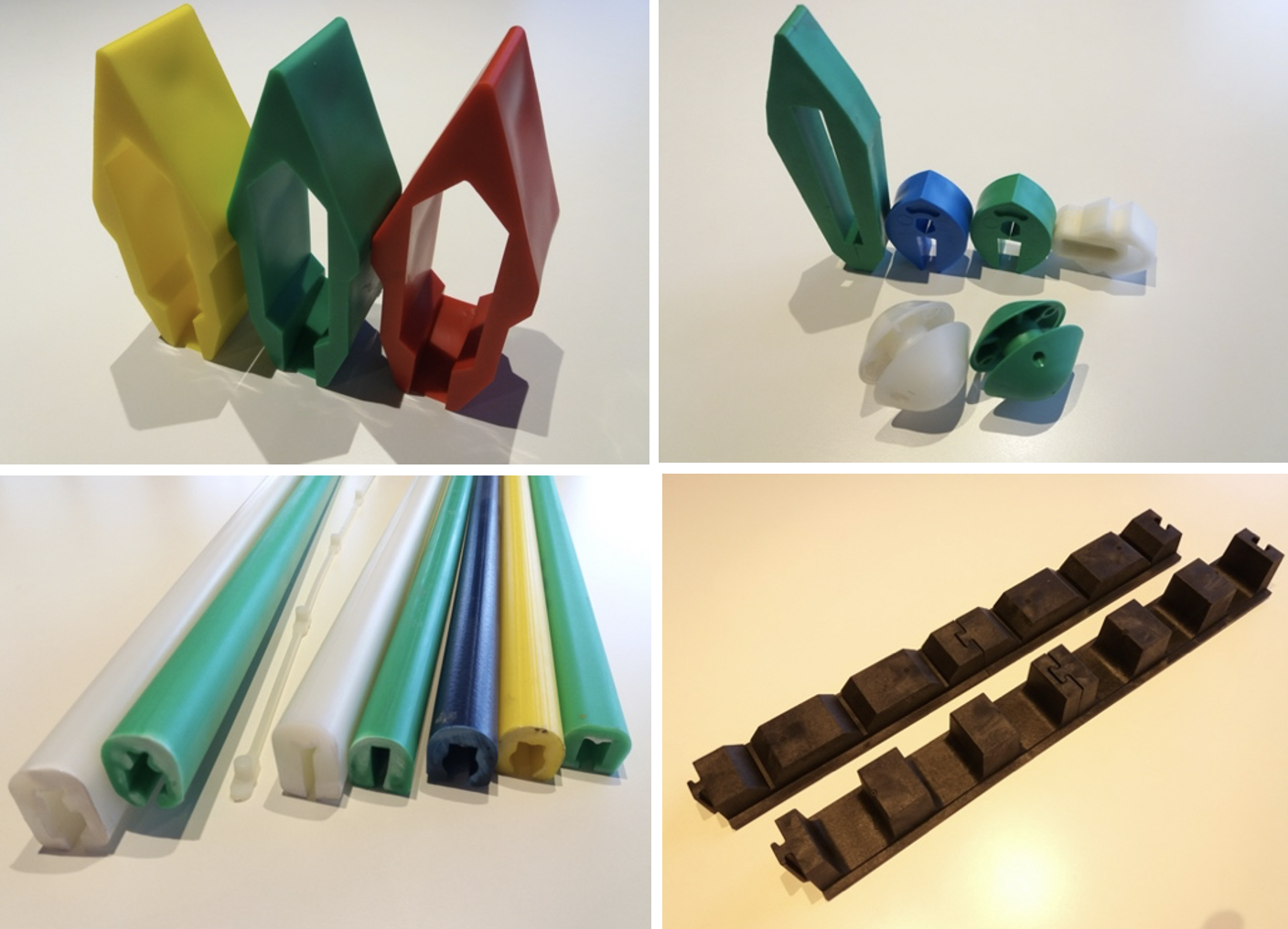

Cell Top Furniture for Zn & Cu Electrolysis, including Insulators, Edge Strips, Anode Spacers & Positioning items, etc., these pieces have been specially-developed for metallurgical operations with raw material coming from own grinding mills.

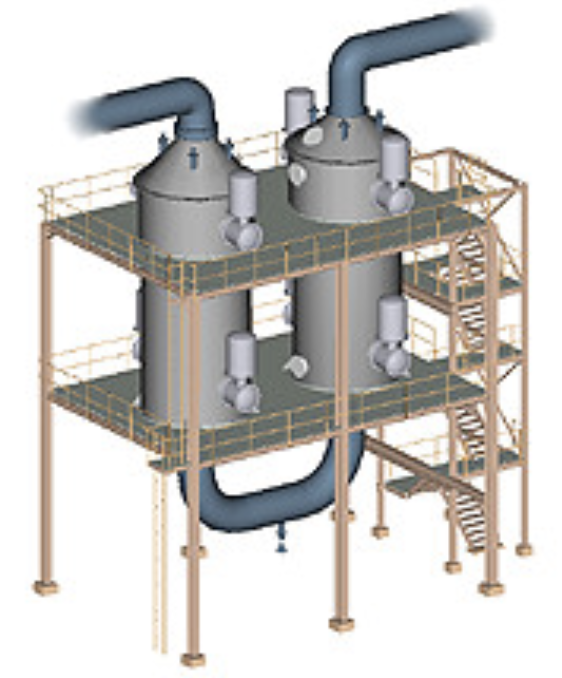

Zincobre Atmospheric Cooling Towers (ZACT) offers cooling needs for existing and new requirements with features including full removal Demister module, high powered motor for increased airflow thereby improving health and safety working conditions.

IRIS, a wireless tool for data acquisition, analytics, actionable insights of various cell parameters for Electrolytic Refining plants for metal extraction. IRIS offers real-time monitoring, trends, and analysis of historical cell house data.

Design, construction and manufacture of transport containers with homogeneous lead, thermoplastic lining, double-walled or with a lead sandwich jacket for dangerous and hazardous goods.

Hugo Petersen has the world’s largest sulphuric acid technologies to help produce Sulphuric acid & Oleum of any kind/quality, SO3/SO 2 as gas or liquid; heavy metal separation & recovery etc.

At the beginning of the 20th century, HUGO PETERSEN set new standards for the production of sulfuric acid with the PETERSEN tower system process by replacing the outdated lead chamber process with new tower system processes. For more than 110 years now, HUGO PETERSEN has been building sulfuric acid plants to meet the highest requirements. Over the decades, optimal concepts have been developed for our customers. Thanks to its knowledge of metallurgical and chemical processes, HUGO PETERSEN offers tailor-made solutions for its customers. HUGO PETERSEN has the largest number of sulfuric acid technologies in the world.

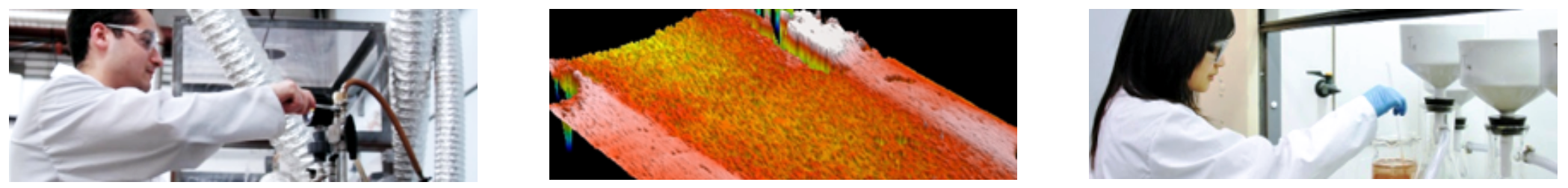

With its gas cleaning technologies developed in-house, HUGO PETERSEN has created optimized processes for a wide range of exhaust gases. Product quality and environmental aspects have the highest priority. These processes ensure optimal conditioning of the gases by means of Quench, Condensation, Gas conditioning & Aerosol separation using Wet Gas Cleaning, Dry Gas Cleaning & Aerosol Separation. In addition, the procedures include heavy metal separation and recovery, e.g., for arsenic, mercury, selenium etc.

Highly efficient SO2 separation through the injection of H2O2. As a post-cleaning stage with a drastic reduction and simultaneous recovery of sulfuric acid up to 60% by weight, SUPER OX is the only process that has proven this in large-scale application.

HUGO PETERSEN GmbH has been active in the field of industrial gas processing and cleaning for more than 70 years. The technology for the production of hydrochloric acid in diluted and concentrated form arose from this environment. With more than 30 years of experience, HUGO PETERSEN GmbH offers concepts with high reliability and absorption performance. In combination with the HP gas cleaning technology, the lowest emission values are achieved.

Develop technological systems for Fiberglass industry including providing Consultancy, Engineering, Supply of Equipment like Chopped Strand Mat Lines, Creels, CSM Choppers, etc.

Services include Chemical Process Modelling, Computational Thermodynamics, Finite Element Modelling, Logistics modelling & Techno-Economic Studies & Computer modelling to provide the best value and the fastest turn-around from concept to implementation.